Efficient inventory management is vital for ensuring that an appropriate level of stock is on hand at the right time for the amount of targeted sales to be realized. Having too much inventory or the wrong kind of inventory during crucial sales periods can ebb your cash flow and reduce profits with the involuntary but obligatory need to offer too many markdowns. On the other hand, if you under buy and under stock and consequently miss sales opportunities as a result of that, then you are not banking your potential profit. Similarly, merchandise may get delivered at an inappropriate time when it isn’t needed and may be unavailable when it is essential. All of these will affect sales and inventory turnover.

A retailer can be sure to stock the right amount of the right products at the right time in the right place by using an effective Open-To-Buy (OTB) plan. Open-To-Buy (OTB) is defined as the merchandise budgeted for purchase during a certain time period, but has not been ordered yet. It is also the process of planning merchandise sales and purchases.

OTB can be calculated in either units or dollars. It is essentially the difference between how much inventory is required to achieve targeted sales and how much is actually available. Consider maintaining an OTB plan for your business as a whole, but also plan for each category of merchandise that you stock. The plan can be maintained on paper, in a spreadsheet or by employing and using one of the right Open-To-Buy software programs/tools.

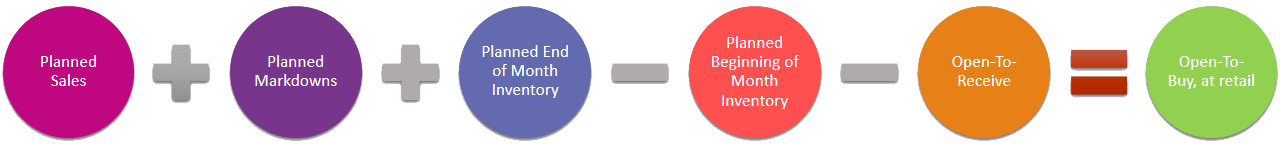

The Open-To-Buy formula is,

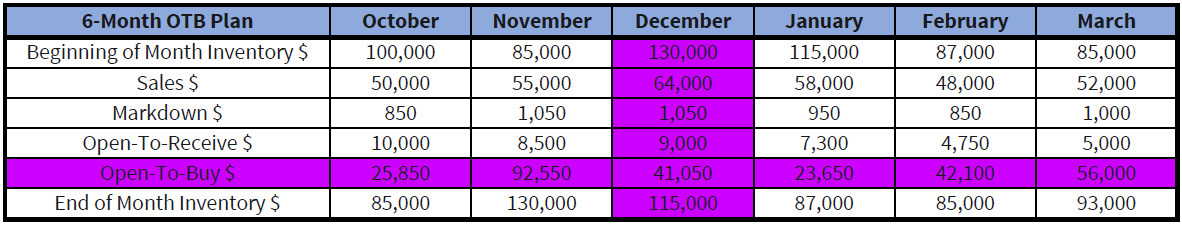

For example, a retailer has an inventory level of $130,000 on December 1st and planned $115,000 end-of-month inventory for December 31st. The planned sales for the store are $64,000 with $1,050 in planned markdowns. Therefore, the retailer has $41,050 Open-To-Buy at retail. Multiply that by the initial markup to arrive at the OTB at cost. So, if the markup is 40%, then the Open-To-Buy at cost will be $16,420.

Keep in mind that many of the figures on your inventory plan are only guidelines. A good thumb rule for business is, if your actual ending inventory is within five percent of your plan, you are doing very well.

It is recommended for OTB to be maintained and monitored for each category separately. Further, OTB should be calculated and monitored not only on retail price, but also keeping a track on the price ranges thereby, getting the required quantity mix across all the ranges. It is important to capture pending deliveries – in transit and any outstanding purchase orders in the OTB calculation. It is also important to close the opened Purchase Orders (PO) if there are no more deliveries expected in that PO, so that it is not added to pending deliveries thereby, leading to an incorrect OTB calculation. In order to take advantage of special buys or to add new products, some of the OTB budget should be held back. This also allows the retailer to react to fast-selling items and quickly replenish supply.

ETP Omni-Channel Retail Merchandise Planning solution improves cash flow with intuitive Open-To-Buy (OTB) planning, helping you to buy right and on time. The cross-channel configuration fine-tunes OTB planning to take timely in-season action. OTB begins with the planning process, is future oriented, provides guidance on how much to buy, and provides benchmarks for evaluating progress and adjusting future plans. The opening stock and OTB values are displayed in the Option plan. These values are auto populated in the plan and therefore there will be no need of creating OTB plan in future.